Automotive Manufacturing Facility Top Physical Security Threats and Integrated Access Control Solutions

- Sep 19, 2025

- 8 min read

South Carolina, North Carolina, and Georgia are rapidly becoming hubs for automotive manufacturing. A prime example is a newly announced electric vehicle production campus near Columbia, SC. This state-of-the-art facility spans over a thousand acres with an initial $2 billion investment – bringing an estimated 4,000 jobs and a plan to produce 200,000 vehicles per year at full capacity. The company behind it recently committed an additional $300 million to build a 200-acre supplier park next door, adding about 1,000 more jobs for battery assembly and parts production. Projects like this underscore the region’s emergence as an automotive powerhouse. However, they also highlight a critical need: protecting these vast facilities with robust physical security. Large sites like this bring exciting growth but not without security challenges.

Why Physical Security Is a Top Priority for Automotive Manufacturing

Modern manufacturing plants are enormous and filled with valuable equipment, inventory, and even proprietary technology. If a facility isn’t properly secured, the costs of an incident can be astronomical for not only replacing stolen or damaged items, but also potential injuries, downtime, and lost productivity.

Manufacturing sites face a wide range of threats: everything from theft and vandalism to workplace violence or even fires can disrupt operations. In the booming automotive industry of the Southeast, facility managers must make security as much a priority as efficiency and output. A strong security program means the difference between smooth operations and costly interruptions.

Top Security Threats for Automotive Manufacturing Facilities

Large automotive factories and supplier parks have unique security concerns. At GenX Security Solutions we have secured multiple large manufacturing facilities to protect and defend against the most critical physical security threats these facilities face. The top four security threats to automotive manufacturing facilities, in order from most to least critical, are theft and unauthorized access, vandalism and sabotage, insider threats and workplace violence, and environmental disasters and accidents. Let's take a closer look at each:

SECURITY THREAT #1: Theft and Unauthorized Access at Automotive Manufacturing Facilities

Stealing valuable parts or equipment is the number one concern. Preventing theft starts with keeping intruders out and closely controlling who can access different areas of the plant.

High-value materials, from vehicle components to raw supplies like batteries, can be tempting targets for thieves. Trespassers might attempt to slip onto the property to steal inventory or even sensitive prototypes. Internal theft is a concern as well; employees and contractors know the facility’s weak points and may take advantage when security is not tight.

SECURITY THREAT #2: Vandalism and Sabotage at Automotive Manufacturing Facilities

Not all intruders want to steal – some may seek to damage property or disrupt operations. Vandals or hostile actors could cut fences, break equipment, or tamper with machinery, causing expensive downtime.

In extreme cases, competitors or disgruntled individuals might attempt sabotage: intentionally breaking critical equipment or interfering with production to halt the plant’s progress. These acts can have serious consequences, potentially even endangering workers. A large facility needs to be prepared to deter and detect malicious damage before it spirals into a major incident.

SECURITY THREAT #3: Insider Threats and Workplace Violence at Automotive Manufacturing Facilities

Sometimes, the threat comes from within. Facility managers need to ensure that background checks, visitor vetting, and emergency plans are in place to mitigate insider risks.

A discontented or careless employee can bypass certain precautions – for example, an insider might leak confidential designs or allow an unauthorized person inside. Worse, incidents of workplace violence or an active shooter are a reality that manufacturing sites must consider. In fact, assaults and attacks by current or former employees, while rare, can have devastating impacts on safety and operations. It’s critical to have a system for employees to report suspicious behavior and to respond quickly if a threat arises on site.

SECURITY THREAT #4: Fire, Accidents, and Natural Disasters at Automotive Manufacturing Facilities

Not all threats are crimes – large industrial sites also face hazards like fires or weather emergencies. Automotive plants (especially those handling battery assembly or chemicals) must be vigilant about fire safety. Ensuring fire alarm life safety systems are in place is just as important as guarding against theft.

An electrical fault or battery malfunction could spark a blaze that spreads quickly if undetected. Likewise, accidents with heavy machinery can endanger lives and halt production. And in the Southeast, severe weather events such as hurricanes or floods can pose risks to facilities. Without proper alarms and emergency systems, a natural disaster or accident could devastate a plant. Ensuring life safety systems are in place is just as important as guarding against theft.

Integrated Industrial Security Solutions for Manufacturing Facilities

To address these threats, new automotive manufacturing campuses, particularly those involved with high-risk and sensitive precision manufacturing, need a layered physical security approach.

The following are key industrial security measures and solutions that GenX Security Solutions has implemented at manufacturing facilities in the Upstate:

PERIMETER SECURITY & ACCESS CONTROL: Protecting the site’s outer boundary first.

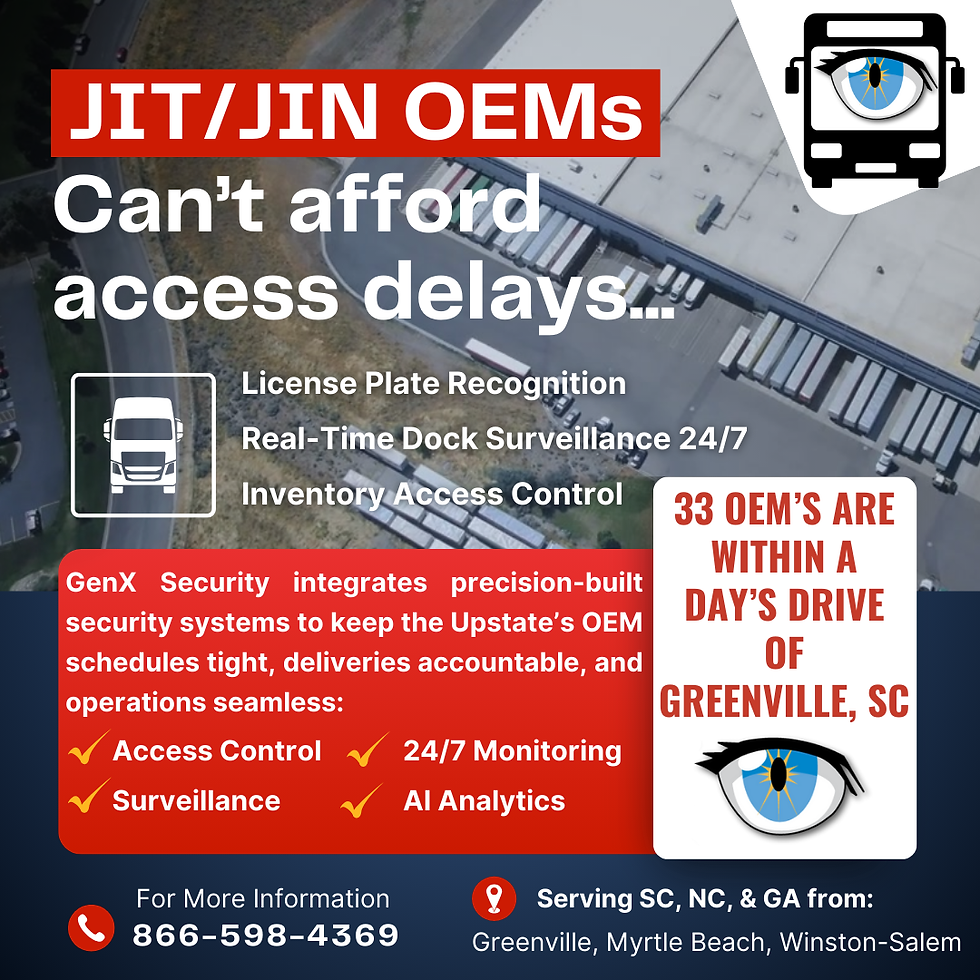

Only authorized personnel and vehicles should be able to enter the grounds. Good perimeter security for large manufacturing facilities includes advanced AI video surveillance of fencing around the property, license plate recognition technology, access controlled gated entrances, and badge-controlled and mobile-credentialed access points.

For example, gated checkpoints with card readers and security guards can verify employees, suppliers, and visitors. Two-factor authorization combining access control with video verification at building entrances with advanced electronic door locks further ensure that each area is restricted to those who belong there.

Mobile surveillance trailers provide excellent camera coverage and can be moved as needed without requiring a traditional power source. By securing the perimeter and all doors, often across multiple buildings that are often not connected except through a solid centralized management system, the facility greatly reduces the chance of unauthorized intruders penetrating secure areas.

24/7 SURVEILLANCE CAMERAS: An extensive network of advanced, ruggedized security cameras is essential for a site of this scale.

High-resolution, AI, and night-vision capable security cameras should monitor all critical areas – the exterior fence line, entry gates, production lines, storage yards, and parking lots. Video surveillance cameras with all-weather and ballistic-resistant housing are excellent options for high-impact zones.

Modern video management systems (VMS) allow security staff to watch multiple camera feeds in real time and quickly review recordings if an incident occurs. Visible cameras act as a deterrent to thieves and vandals, who know they are being watched.

Today’s systems can even include intelligent AI-powered analytics that alert staff to unusual activities (for instance, if someone is walking in a restricted zone after hours and tracking person or vehicle based upon search parameters such as "red bag" or "ball cap"). With constant eyes on the facility, any intrusion or problem can be caught early.

STRUCTURED CABLING & CONNECTIVITY: Behind every high-tech security system is a robust network.

Large manufacturing plants require miles of structured cabling infrastructure (high-grade copper and fiber optic cables) to connect all of the cameras, access control panels, alarms, and communication devices. Even “wireless” tech like Wi-Fi and smartphones depend on a wired backbone. In fact, wireless doesn’t work without wires – every wireless access point on site connects to the network through cables.

If the network of structured cabling infrastructure is weak then critical systems (from security cameras to production equipment) won’t perform reliably. That’s why new facilities must install a strong cabling infrastructure from day one. Fiber-optic lines often tie together distant buildings or alarm panels across a 200-acre supplier park, ensuring instant communication back to the main security control room.

A well-designed cabling and network infrastructure is the unseen hero that keeps security devices online, keeps data flowing, and supports the plant’s high-tech operations.

FIRE ALARMS & LIFE SAFETY SYSTEMS: Protecting the facility’s people is paramount.

Comprehensive fire alarm systems should cover all buildings and production areas. This means smoke detectors, heat sensors, and pull stations installed throughout the plant and warehousing areas. In high-risk zones (like battery assembly or paint shops), specialized detectors can provide early warning of issues (for example, sensors that detect chemical fumes or rapid temperature increases). These alarms must be integrated so that if a fire is detected, loud sirens and strobes alert everyone to evacuate, and the system automatically notifies local fire authorities.

Regular inspections and tests of the fire alarm ensure it will work when it’s needed. In addition to fire alarms, facilities should have emergency lighting and clearly marked exit routes. Planning for occupant safety, through drills and training, goes hand-in-hand with the technology. In an emergency, saving lives and minimizing damage depends on these life safety systems functioning without a hitch.

INTEGRATED SECURITY MONITORING: Finally, tying everything together is key.

A modern automotive plant benefits from a centralized security management system. This could be a dedicated Security Operations Center on site or a cloud-based platform that facility managers monitor.

In either case, integration means all the security components work in unison. For instance, when an alarm sensor goes off at a back door after hours, the system can automatically pull up the nearest camera feed for the security team to review. Access control logs, camera feeds, and alarm status should all be visible on a single dashboard.

Such integration not only speeds up incident response but also provides useful data for audits and improvements. Facility managers can generate reports on who accessed certain areas and receive real-time alerts for any irregularities. The goal is situational awareness: knowing what’s happening across the entire campus at any given moment. With the right integrated system, a lean security team can effectively manage a very large and complex facility.

Choosing the Best Local Manufacturing Security Integration Company

New automotive manufacturing facilities represent an exciting investment in the future – bringing jobs, innovation, and economic growth. To protect that investment, companies must take proactive steps to address physical security from day one. When a plant is well-secured, leaders can focus on meeting production goals and building world-class vehicles, confident that their site and staff are safeguarded.

Implementing these solutions is not a one-size-fits-all job. Each facility in the Southeast may face unique local challenges – from climate considerations (heat, humidity, storms) to regional compliance standards. It helps to work with the best regional industrial/manufacturing security integration company, such as GenX Security Solutions, who understands the landscape in South Carolina, North Carolina, and Georgia.

At GenX Security Solutions, we specialize in helping manufacturing and industrial facilities achieve that peace of mind. We proudly serve businesses across the Southeast – from South Carolina to North Carolina to Georgia – with cutting-edge security systems, access control, structured cabling and fiber, video surveillance cameras, commercial fire alarms, and 24/7 surveillance integration. We also provide fleet management GPS technology and services to the region.

Our team works closely with facility managers to design and install solutions tailored to each site’s needs and risks. As the Southeast’s automotive industry continues to grow, GenX Security is committed to keeping these operations secure every step of the way. We can ensure that the region’s new automotive hubs are not only productive and innovative, but also safe and secure for years to come.

Please reach out to a member of the GenX Security sales and accounts management team for a fast, fair, and always FREE quote for your manufacturing facility.

Experience the next generation of interactive security services and solutions with GenX Security.

With custom security integration solutions come custom quotes designed for your needs. Please contact us by clicking here or calling 866-598-4369.

At GenX Security Solutions, we proudly serve businesses in all locations across South Carolina, North Carolina, and Georgia with cutting-edge commercial security systems, access control solutions, structured cabling, fire alarms, and professional audio/visual integration. From bustling cities like Greenville and Raleigh to growing industrial hubs like Winston-Salem to hospitality hot spots like Myrtle Beach, our team delivers tailored solutions to meet your business’s unique needs.

Please visit our state-specific pages for more information on our services in various industries. We serve all cities in the Upstate and surrounding, including:

Aiken, SC | Asheville, NC | Alpharetta, GA |

Anderson, SC | Burlington, NC | Athens, GA |

Beaufort, SC | Cary, NC | Atlanta, GA |

Charleston, SC | Chapel Hill, NC | Augusta, GA |

Columbia, SC | Charlotte, NC | Carrollton, GA |

Florence, SC | Concord, NC | Columbus, GA |

Goose Creek, SC | Durham, NC | Dalton, GA |

Greenville, SC | Fayetteville, NC | Douglasville, GA |

Greenwood, SC | Gastonia, NC | Gainesville, GA |

Greer, SC | Goldsboro, NC | Hinesville, GA |

Hilton Head Island, SC | Greensboro, NC | Macon, GA |

Lexington, SC | Hickory, NC | Marietta, GA |

Mount Pleasant, SC | High Point, NC | Newnan, GA |

Myrtle Beach, SC | Jacksonville, NC | Peachtree City, GA |

North Charleston, SC | Kannapolis, NC | Rome, GA |

Orangeburg, SC | Raleigh, NC | Roswell, GA |

Piedmont, SC | Rocky Mount, NC | Sandy Springs, GA |

Rock Hill, SC | Wilmington, NC | Savannah, GA |

Spartanburg, SC | Wilson, NC | Valdosta, GA |

Summerville, SC | Winston-Salem, NC | Warner Robins, GA |

![2020 Roaring Twenties Winner Badge[44136].jpg](https://static.wixstatic.com/media/c44162_312513fcb3514e3ca71a2a18b458369a~mv2.jpg/v1/fill/w_129,h_52,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/2020%20Roaring%20Twenties%20Winner%20Badge%5B44136%5D.jpg)

Comments